CNC centre Orion

Wood Plastics

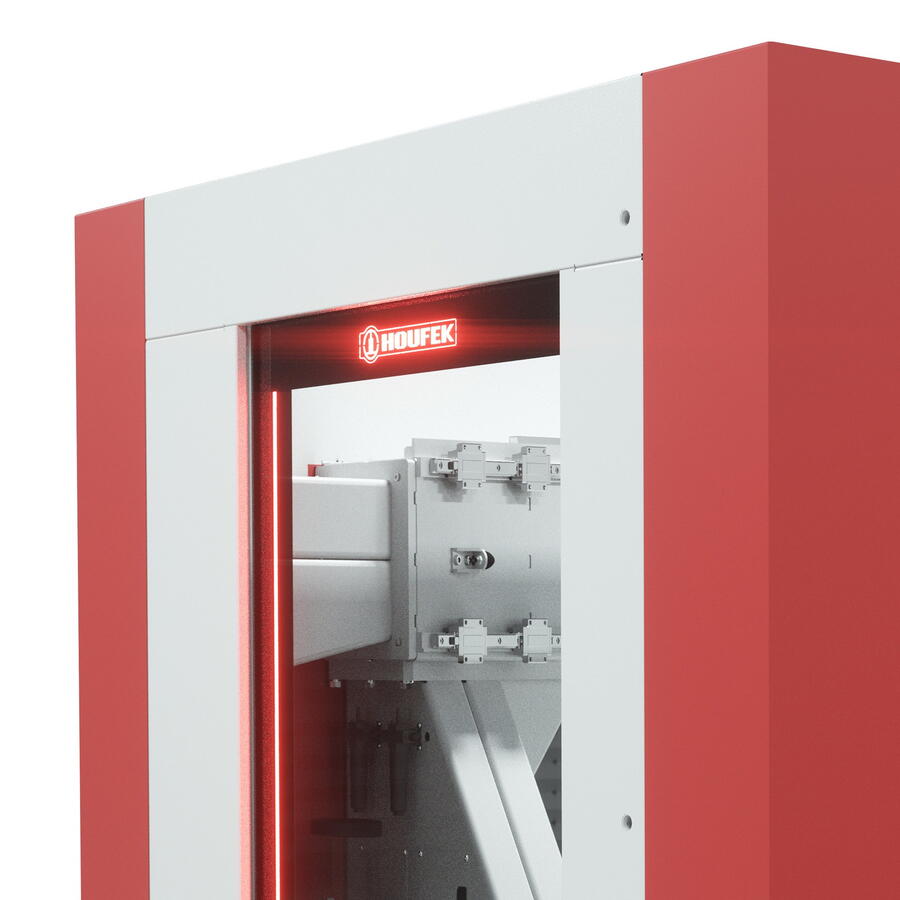

The basic design of the machine is made of welds from sheet metal cinders that are subsequently annealed to reduce internal strains, and machined. For better absorption of vibration the basic construction is filled with concrete, which responds with the weight of the machine at about 3,8 t. Characteristic feature is the console construction of the cross-member (arm). The centre is fitted with modern control system SIEMENS SINUMERIC 840 D – SL The control system cooperates with a number of CAD systems which are commonly used in the construction practise (Auto CAD, SOLID WORKS, PRO-E, etc.), and it enables programming by means of parameters or maker, data import from CAD systems by means of DXF files and graphic simulation of the processing process. It is possible to graphically display the location of brackets with clamping blocks, the types of tools, hoppers with tools, etc. The operating environment of the control system is displayed on LCD monitor placed in the switchboard cabinet. After programming, the machine can be controlled by means of manual controller. The system control modules can be remotely connected via internet with the servicing centre of HOUFEK.

We produce the machine since 2012

Use

The CNC centre Orion is designed for:

- production of furniture parts, window frames, etc.

Interesting product

- tri-axial woodworking centre

- production of furniture parts, window frames, etc.

- up to the height of the workpiece of 150 mm.

Specifications

| Maximum workpiece dimension in axis Y | 1 550 mm |

| Maximum workpiece dimension in axis Z | 260 mm |

Standard equipment

- basic design Console / raster desk

- main milling electric spindle

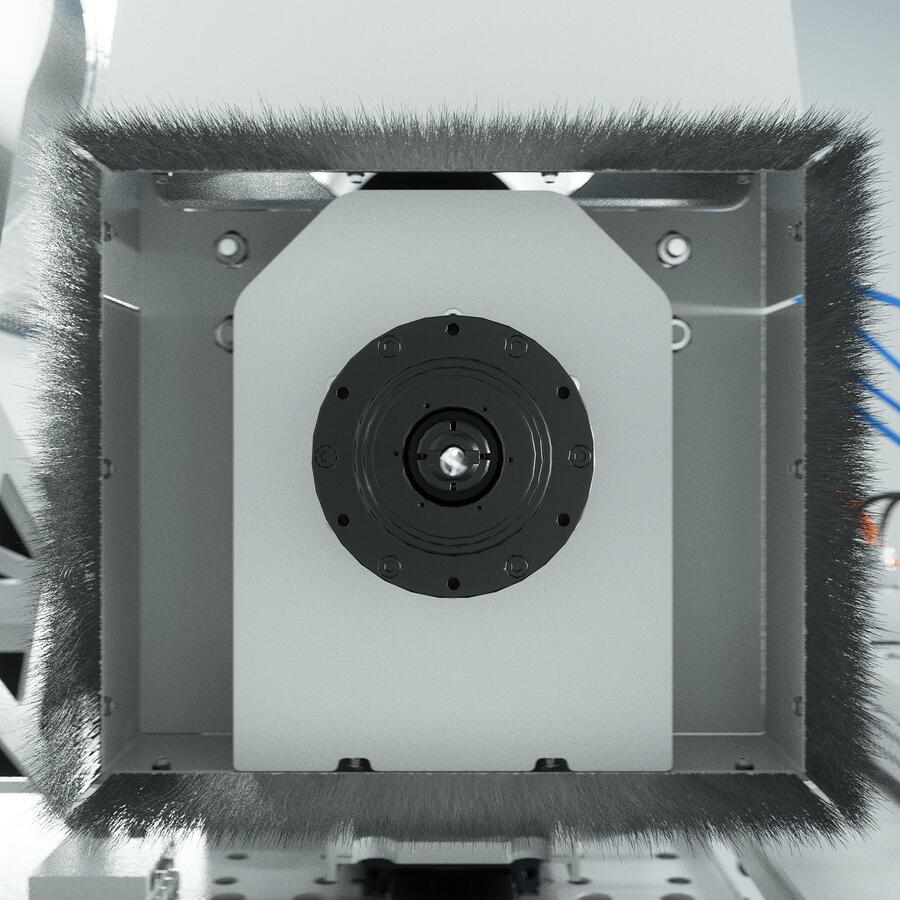

- drilling head

- shifting tool hopper

- greasing Suction connection

- safety devices

Optional equipment

- electric spindle HSD 4,6 kW

- electric spindle HSD 9 kW

- electric spindle HSD 12 kW

- preparation for axis C

- gradually controlled axis C HSD

- electric spindle HITECO 15 kW

- gradually controlled axis C HITECO

- horizontal mortiser aggregate

- rotary tool hopper (7 pcs )

- rotary tool hopper (14 pcs )

- special tool hopper ISO

- special tool hopper HSK

- desk frame

- front and side stop pins for Desk frame

Ask about this product

45 countries

We export to 45 countries all over the worlds. Our machines run also in overseas states.

Quality

Houfek machine have unique rigid design. We care about maximum quality of all parts and components.

Service

We offer service and replacement of parts besides sales.

Own development

We are unique. All our machines are result of our own development.