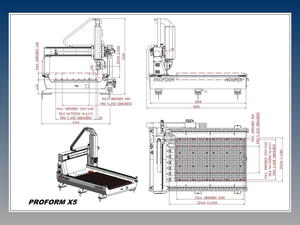

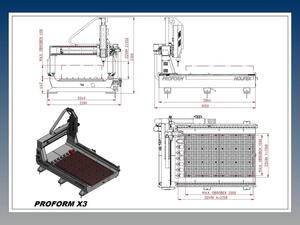

CNC woodworking centre Proform

Wood Plastics Composite

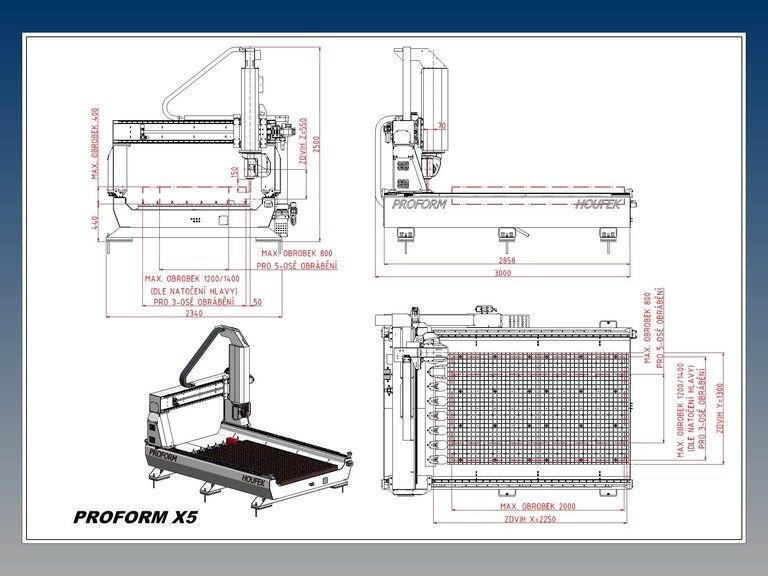

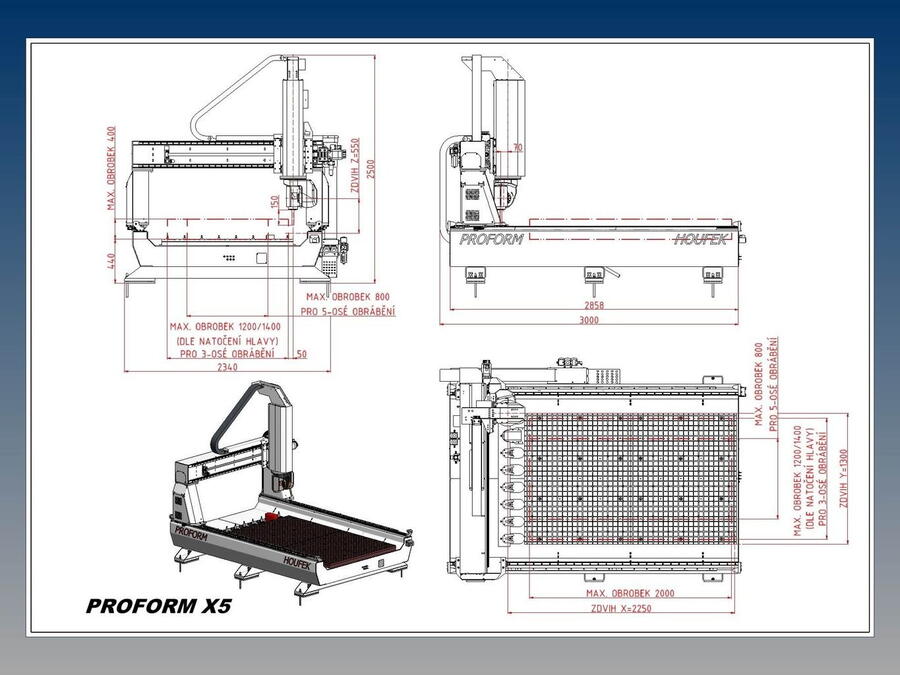

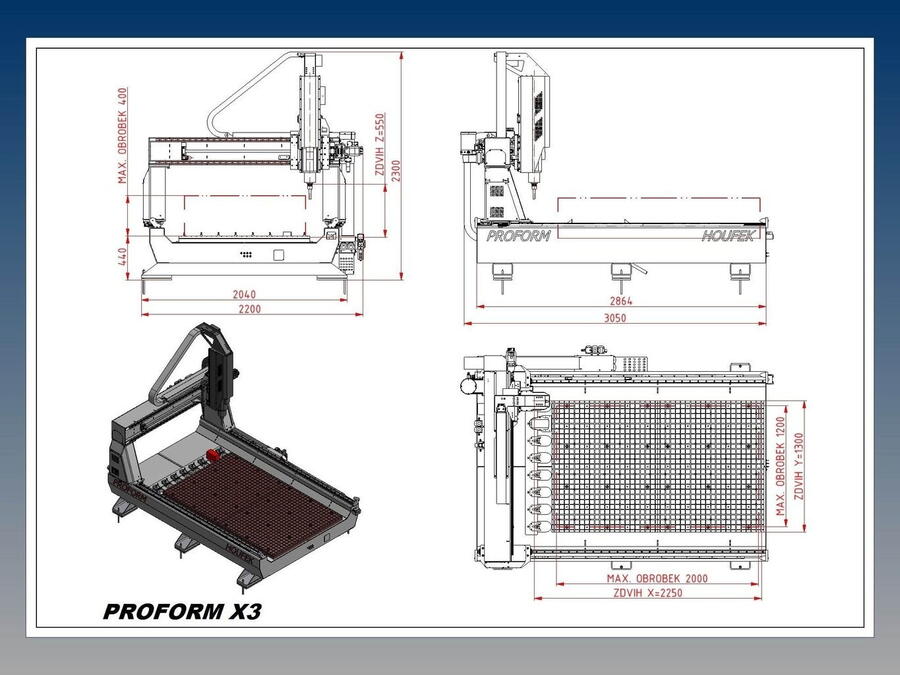

The basic design of the machine is made of welds from sheet metal cinders that are subsequently annealed to reduce internal strains, and machined. The characteristic feature is a portal (bridge) construction of the cross-member with clamped driving servomotors of the X axis (gantries) on both sides.

The centre is fitted with modern control system SIEMENS SINUMERIC 840 D – SL The control system cooperates with a number of CAD systems which are commonly used in the construction practise (SOLID WORKS, PRO-E, etc.) The operating environment of the control system is displayed on LCD monitor placed on the moving panel. After programming, the machine can be controlled by means of manual controller. The system control modules can be remotely connected via internet with the servicing centre of HOUFEK.

We produce the machine since 2010

Use

The CNC centre Proform is designed for:

- production of intricate furniture components and wooden or Styrofoam models for metal foundries, and similar.

Interesting product

- five-axis woodworking centre equipped with a dual-axis head

- production of intricate furniture components and wooden or Styrofoam models for metal foundries, and similar.

Specifications

| Maximum dimension of the workpiece in axis X | 2 000 mm |

| Maximum workpiece dimension in axis Y | 1 400 mm |

| Maximum workpiece dimension in axis Z | 400 mm |

3D Model

Standard equipment

- smooth desk-type G

- raster desk-type R

- desk with the t-groove - type T

- main milling electrical spindle

- overhead tool magazine

- lubrication

- auxialiary outputs of compressed air and vacuum

- safety devices

- control - siemens sinumerik 840D-SL

Optional accessories

- electric spindle 18 Kw

- extension of the X axis stroke of 1.000mm

- extension of the Z axis stroke of 500mm

- rot. Instrument cartridge

- aluminium smooth table with threaded steel inserts M12

- aluminium raster tale with vacuum distribution

- external rulers of lin. Axises X, Y, Z

- external rulers of lin. Axises B, C

- spindle with position gauges of the rotor

- external tool blowing

- external cooling of the machine

- tool probe

- spindle probe

- spindle shaving vacuuming

- laser projector

- vacuum pump 250m3/h

- vacuum pump 500 m3/h

- vacuum reservior 500l

- CAM software TOP SOLID

Ask about this product

45 countries

We export to 45 countries all over the worlds. Our machines run also in overseas states.

Quality

Houfek machine have unique rigid design. We care about maximum quality of all parts and components.

Service

We offer service and replacement of parts besides sales.

Own development

We are unique. All our machines are result of our own development.