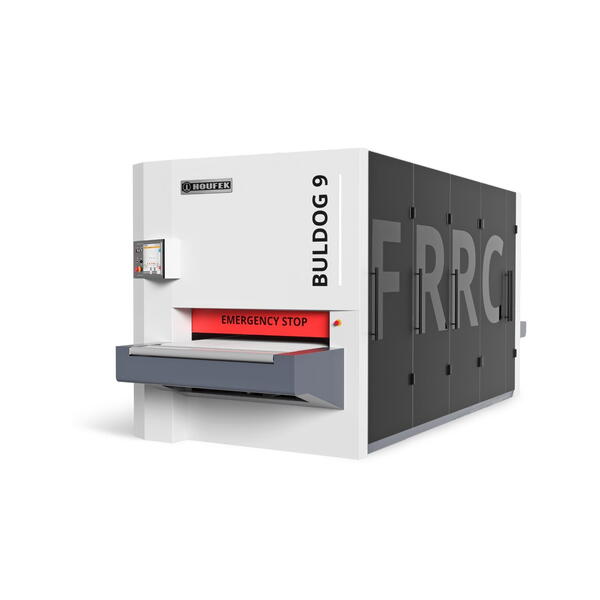

Wide belt sander Buldog 5 1300

Massif Wood Veneer Varnish

Original construction of the production series if machines Buldog 5 was developed for customers who require simplicity, reliability, and quality of all sanding technologies. The sanding of massif, veneer surfaces, and varnishes is a simple matter for this machine. The machine is recognized for its robustness, reliability, and variability of sanding aggregates combinations. The assets of wide-belt sanders series Buldog – after producing several thousands of pieces – is the verified satisfaction and reliability at the customers worldwide.

Product benefits

We produce the machine since 2000

We delivered the machine to 18 of the world's countries

We produced the machine for 1 200 of satisfied customers

Use

Wide-belt sander Buldog 5 is designed for:

- sanding workpieces made from wood, wood base composite materials, paper and some plastic materials and metals

- the sanded materials must not sparkle during sanding or change its features and shape due to increasing temperature occuring during sanding

Interesting product

- multipurpose machine with the option of fitting with various operating aggregates verified robust construction

Specifications

| Working width | 1 350 mm |

| Sanding belt length | 2 200 mm |

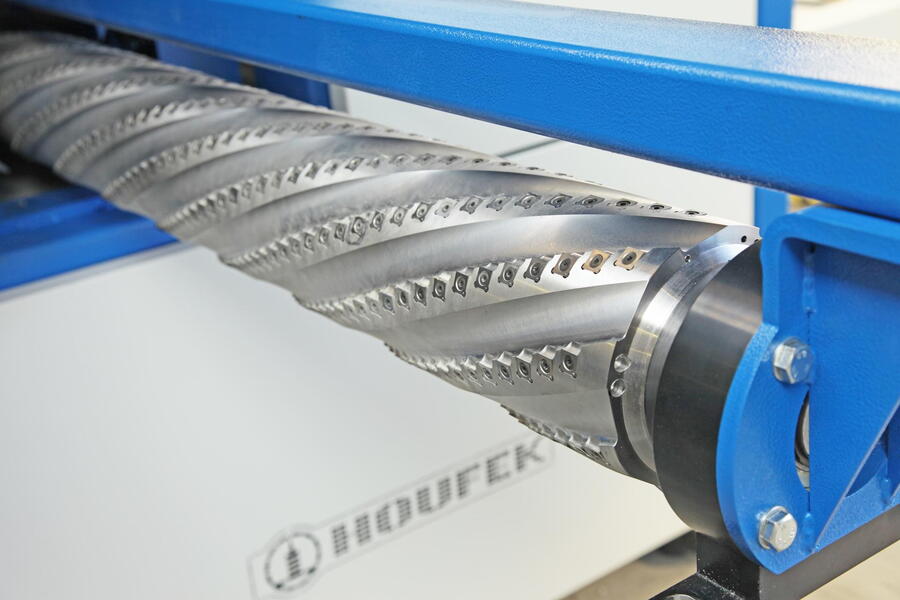

| Contact roller diameter | 160-200 mm |

| Maximum workpiece height | 160 mm |

| Min. workpiece height | 3 mm |

| Sanding belt speed | 18 m/min |

| Voltage / frequency | 3/N/PE 400V/50Hz V / Hz |

| Weight | 1 420 kg |

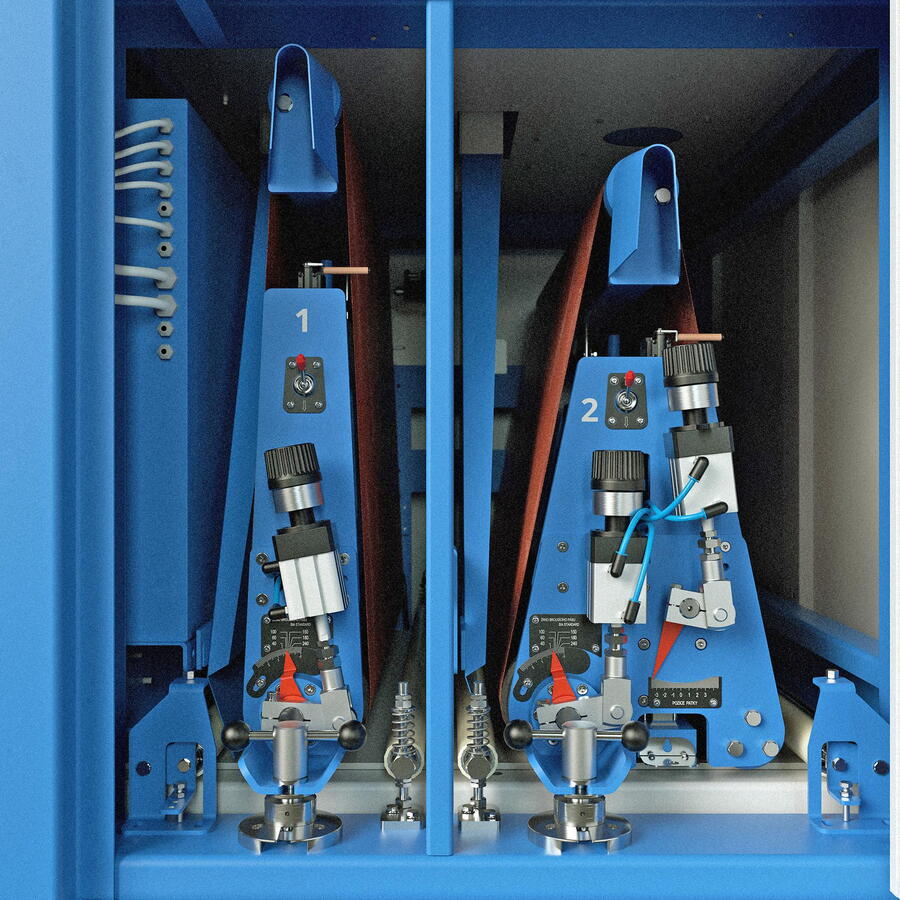

3D Model

Standard equipment

- 1. working roller rubbered - D=160 mm, 90 Sh (for version R, C, RR, RC, RRR, RRC)

- 2. working roller rubbered - D= 160 mm, 90 Sh (for version FC RRR, RRC, FRC)

- 2. working roller rubbered - D=160 mm, 45 Sh (for version RR, RC)

- 3. working roller rubbered - D=160 mm, 45 Sh (for version RRR, RRC, FRC)

- Sliding sanding unit type F, D=180 mm (for version FC, FRC)

- divided infeed pressure segments

- outfeed pressure bar - sanding belt length 2200 mm

- Motorized table height adjustment - workpiece height - 3-160 mm

- Automatic star/delta switch

- Pneumatic lifting working rollers from front panel

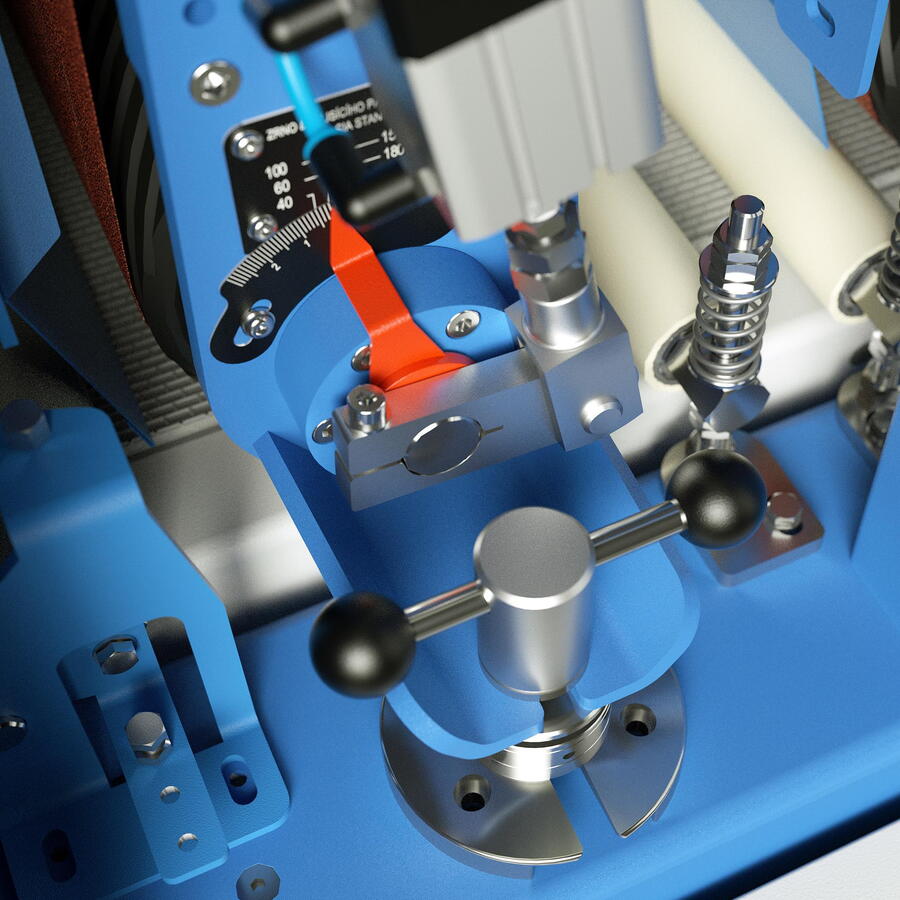

- Hard pad - mechanically adjustable (for version C, RC, FC, RRC, FRC)

- Amperemeters for measuring motor current of sanding units

- Optoelectronic sensor of sanding belt oscillation

- Automatic feed belt tracking

- Table positioner - workpiece height

- Electronic measuring of table position with digital display

- Feed belt motor frequency inverter - speed 3-15 m/min

- Rubbered pressure rollers

- Emergency - Main motor electromagnetic disc brake

- Mechanical limitation of maximum material removal

- Noise protection

- CE certification

Optional accessories

Motors/frequency inverters

| |

Working rollers

| |

Machine control

| |

Sanding pads

| |

Brushes and Cleaning units

| |

Others

|

Ask about this product

45 countries

We export to 45 countries all over the worlds. Our machines run also in overseas states.

Quality

Houfek machine have unique rigid design. We care about maximum quality of all parts and components.

Service

We offer service and replacement of parts besides sales.

Cooperation

We cooperate with schools. We organize excursion and cooperate on school projects.

sand up to 1300 mm wide material

sand up to 1300 mm wide material

motor power 11 kW - possibility to increase to 18,5 kW

motor power 11 kW - possibility to increase to 18,5 kW